UFACTORY Robotic Arm with Dexterous Hand RH56DFX

Project Overview

This project demonstrates an application based on the UFACTORY robotic arm and the INSPIRE-ROBOTS dexterous hands RH56DFX series.

Users can quickly control the dexterous hand via UFACTORY Studio software, implement fast grasping and other applications.

The following videos show the dexterous hand grasping eggs and oranges, drilling cardboard with an electric drill, and controlling a computer mouse to switch web pages.

Hardware Requirements

- Robotic Arm: UFACTORY- 850, xArm series (version 1305)

- Dexterous Hand: Inspire Robots - RH56DFX-Left / RH56DFX-Right

Hardware Connection

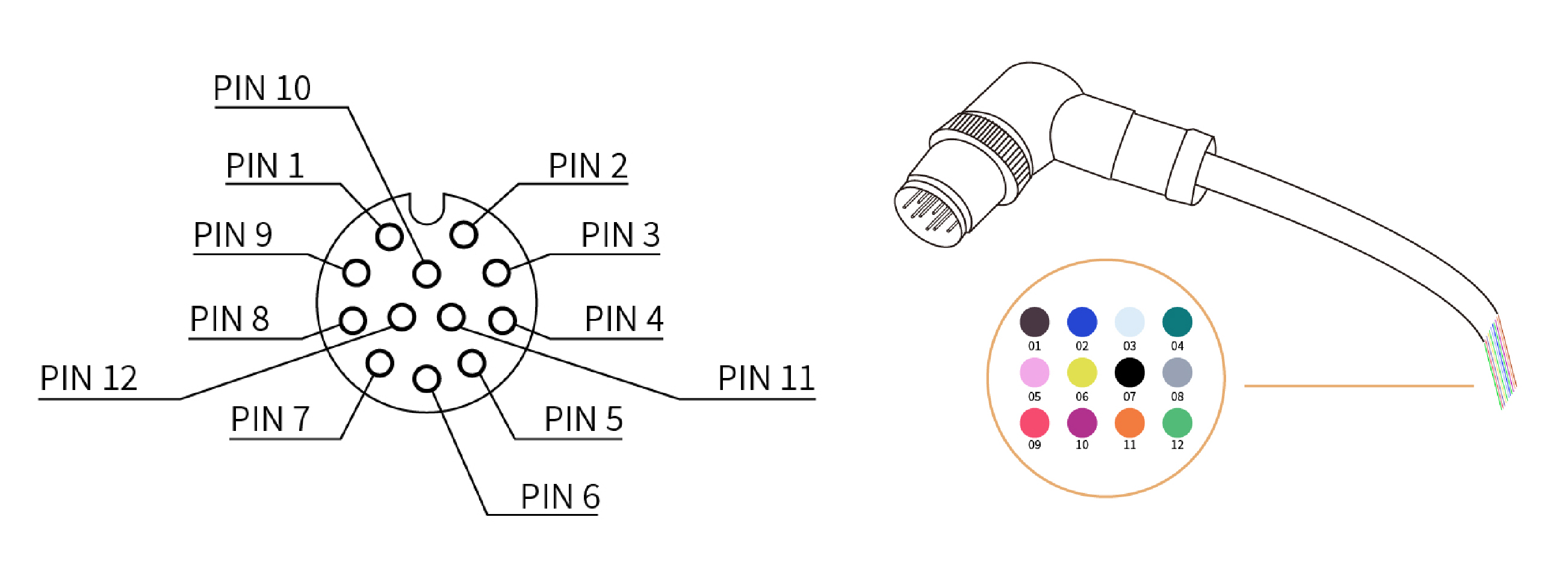

Robotic Arm End Effector Definition

- Plug in Connection

| Pin | Color | Signal | Pin | Color | Signal |

|---|---|---|---|---|---|

| 1 | Brown | +24V (Power) | 7 | Black | Tool Output 0 (TO0) |

| 2 | Blue | +24V (Power) | 8 | Gray | Tool Output 1 (TO1) |

| 3 | White | 0V (GND) | 9 | Red | Tool Input 0 (TI0) |

| 4 | Green | 0V (GND) | 10 | Purple | Tool Input 1 (TI1) |

| 5 | Pink | User 485-A | 11 | Orange | Analog Input 0 (AI0) |

| 6 | Yellow | User 485-B | 12 | Light Green | Analog Input 1 (AI1) |

- Contact Connection

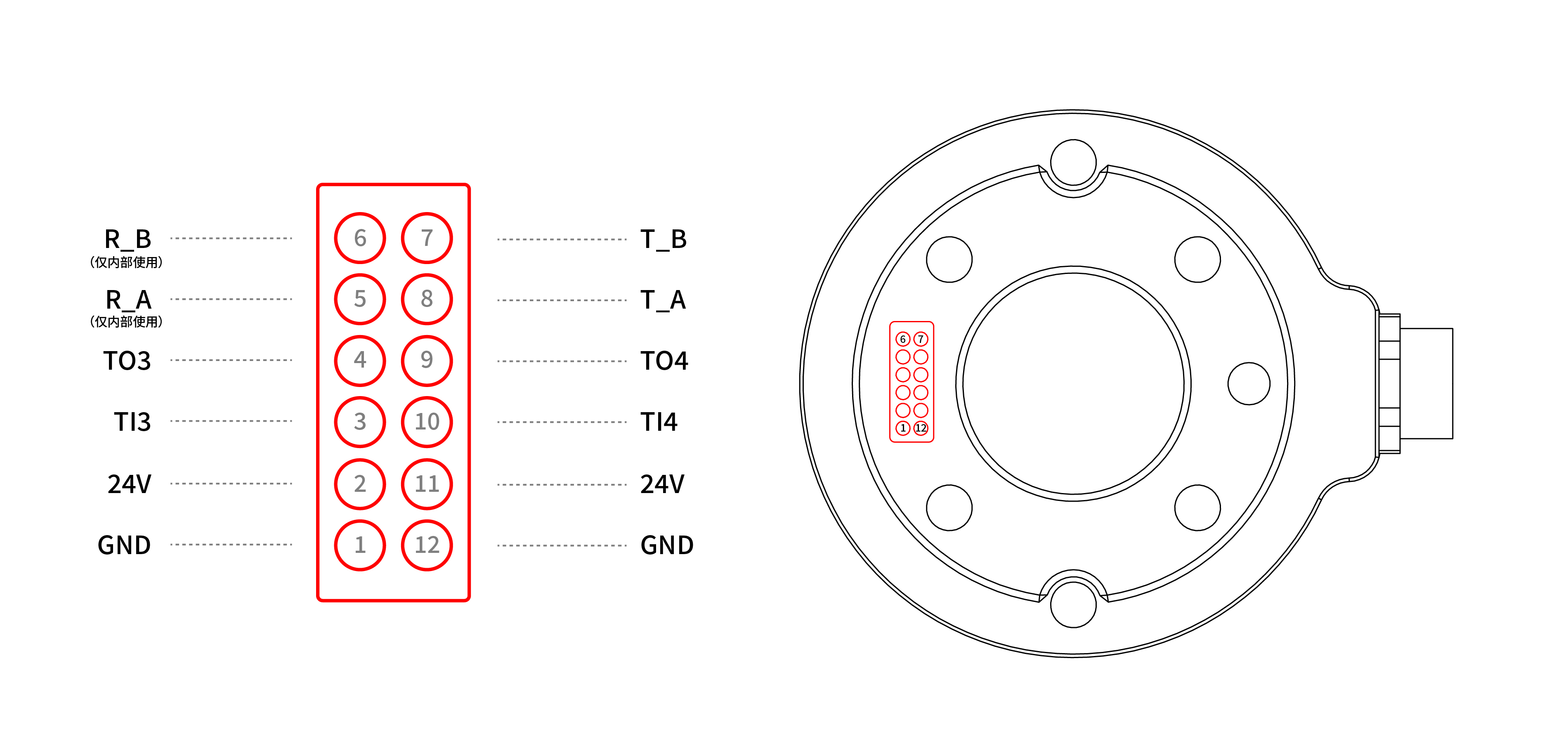

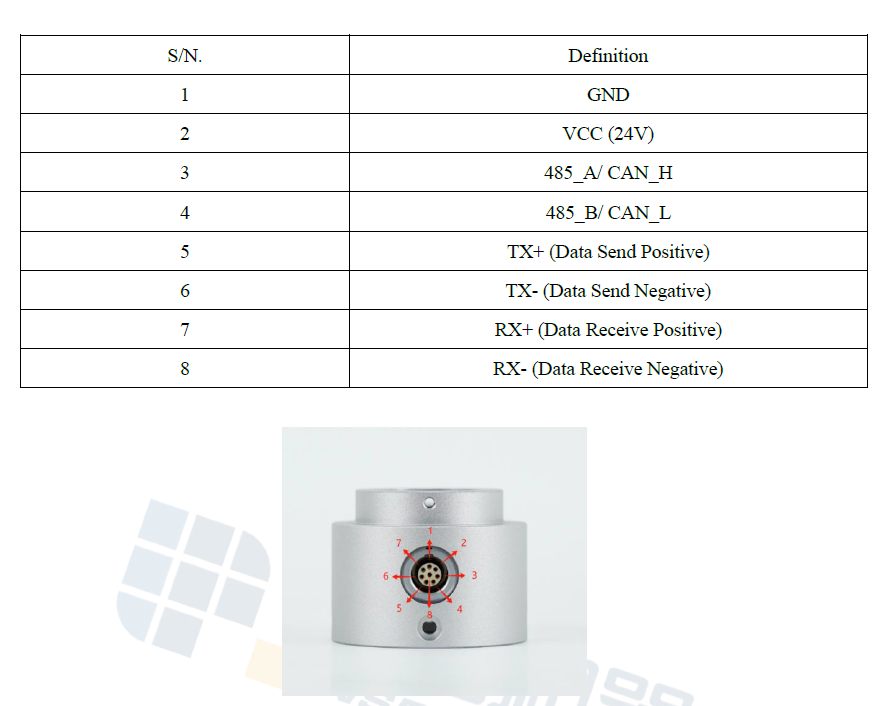

RH56DFX Dexterous Hand Definition

Note:

The robotic arm end and the dexterous hand cannot be directly connected. Please contact Inspire Robots for an aviation adapter connector.

Control Methods

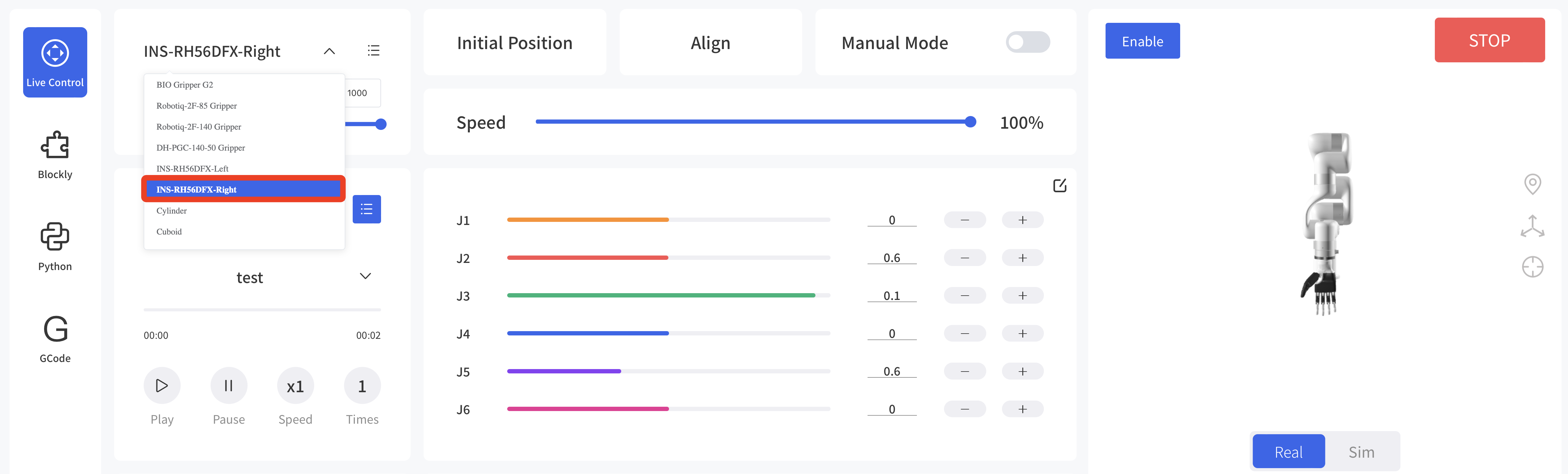

UFACTORY Studio Control

UFACTORY Studio Version: ≥ V2.7.0

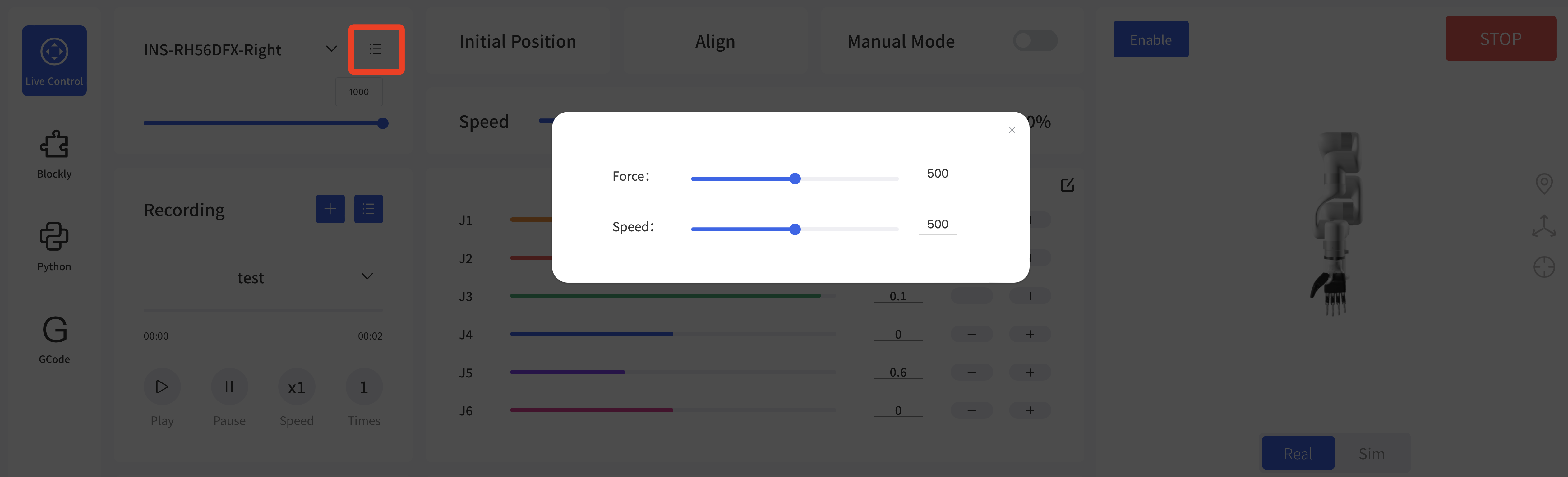

1. Real-Time Control Interface

Select INS-RH56DFX-Left or INS-RH56DFX-Right.

A pop-up will ask to set the robotic arm baud rate to 115200.

Adjustable parameters: position, force, speed.

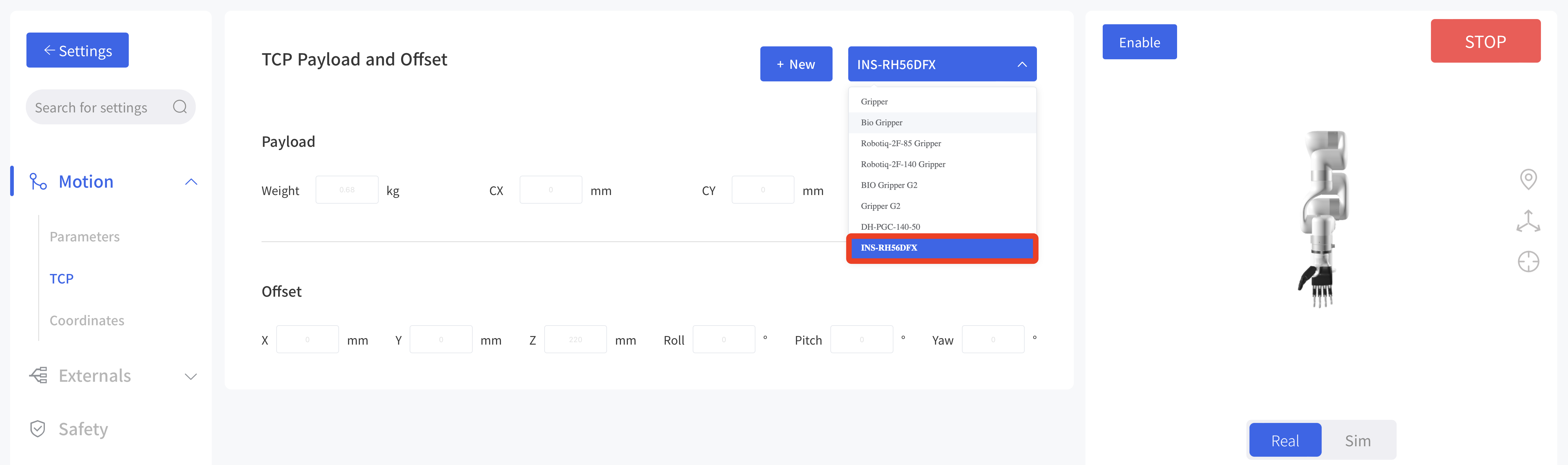

2. TCP Settings

Go to Settings - Motion Parameters - TCP Settings, then select INS-RH56DFX and save.

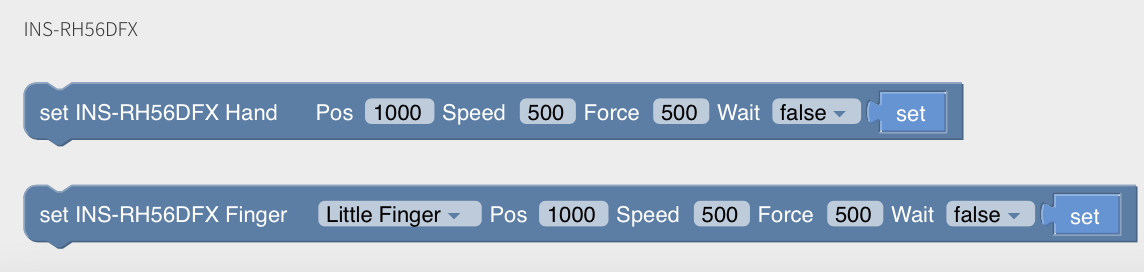

3. Blockly Control

Blockly provides two blocks for the dexterous hand, allowing control of either the entire hand or individual fingers.

Optional parameters:

- Finger: Little finger, Ring finger, Middle finger, Index finger, Thumb Flexion, Thumb Rotation, Entire hand

- Position: 0–1000

- Speed: 0–1000

- Force: 0–1000

- Wait option: Whether to wait for the current command to finish before sending the next (synchronous or asynchronous)

Python SDK Control

1. Set UFACTORY Robotic Arm End Baud Rate

code = arm.set_tgpio_modbus_baudrate(115200)2. Perform 485 Communication

code, res_data = arm.getset_tgpio_modbus_data(modbus, timeout=100)Example: set_yinshi_rh56_gripper.py