0.1 mm Displacement Test for 850 and xArm 6

Measurement Method

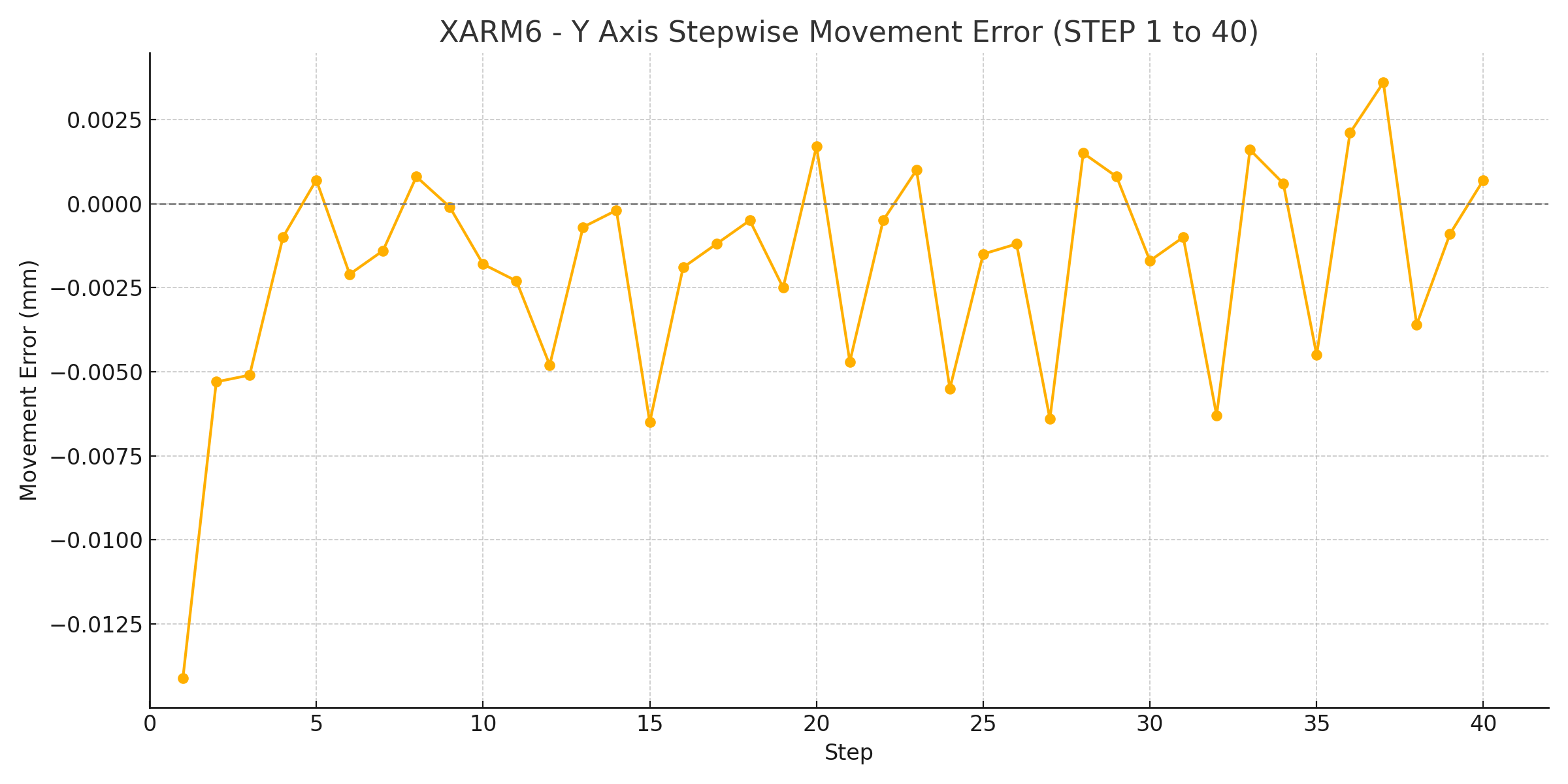

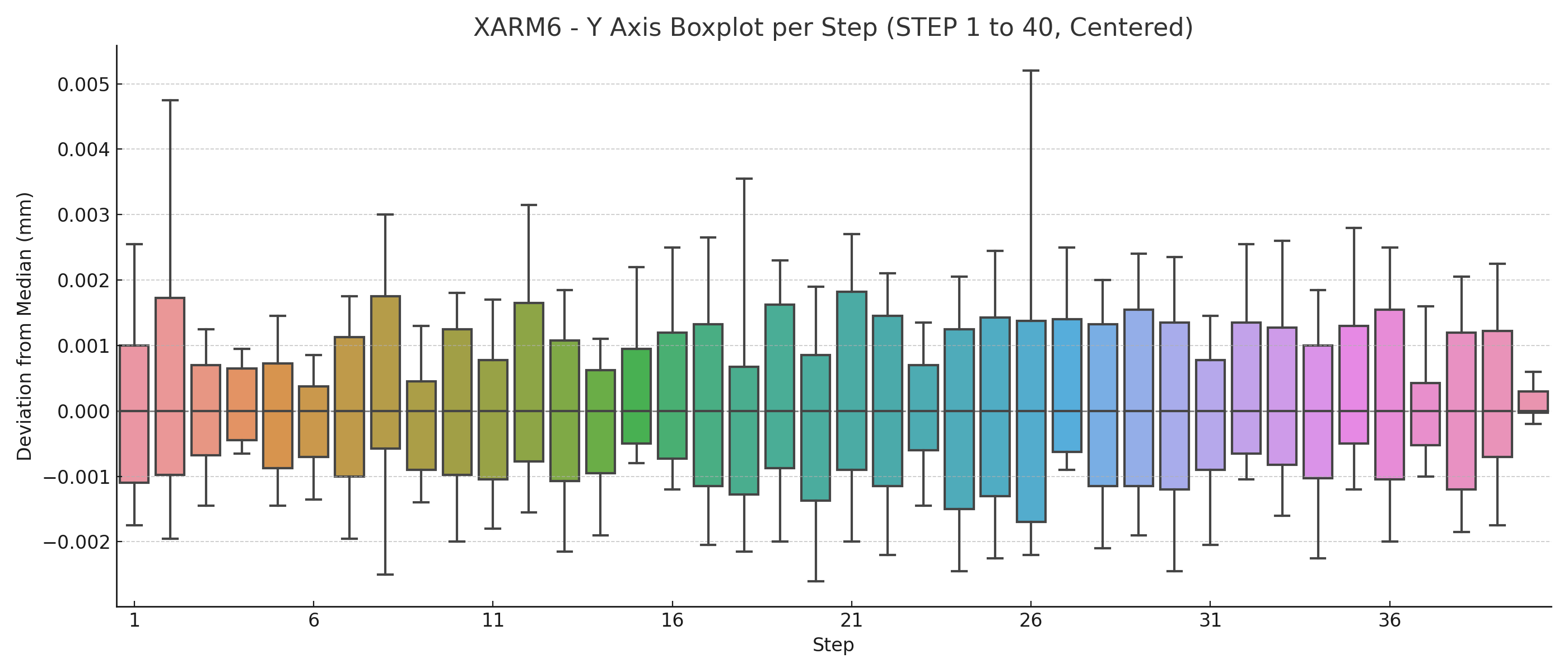

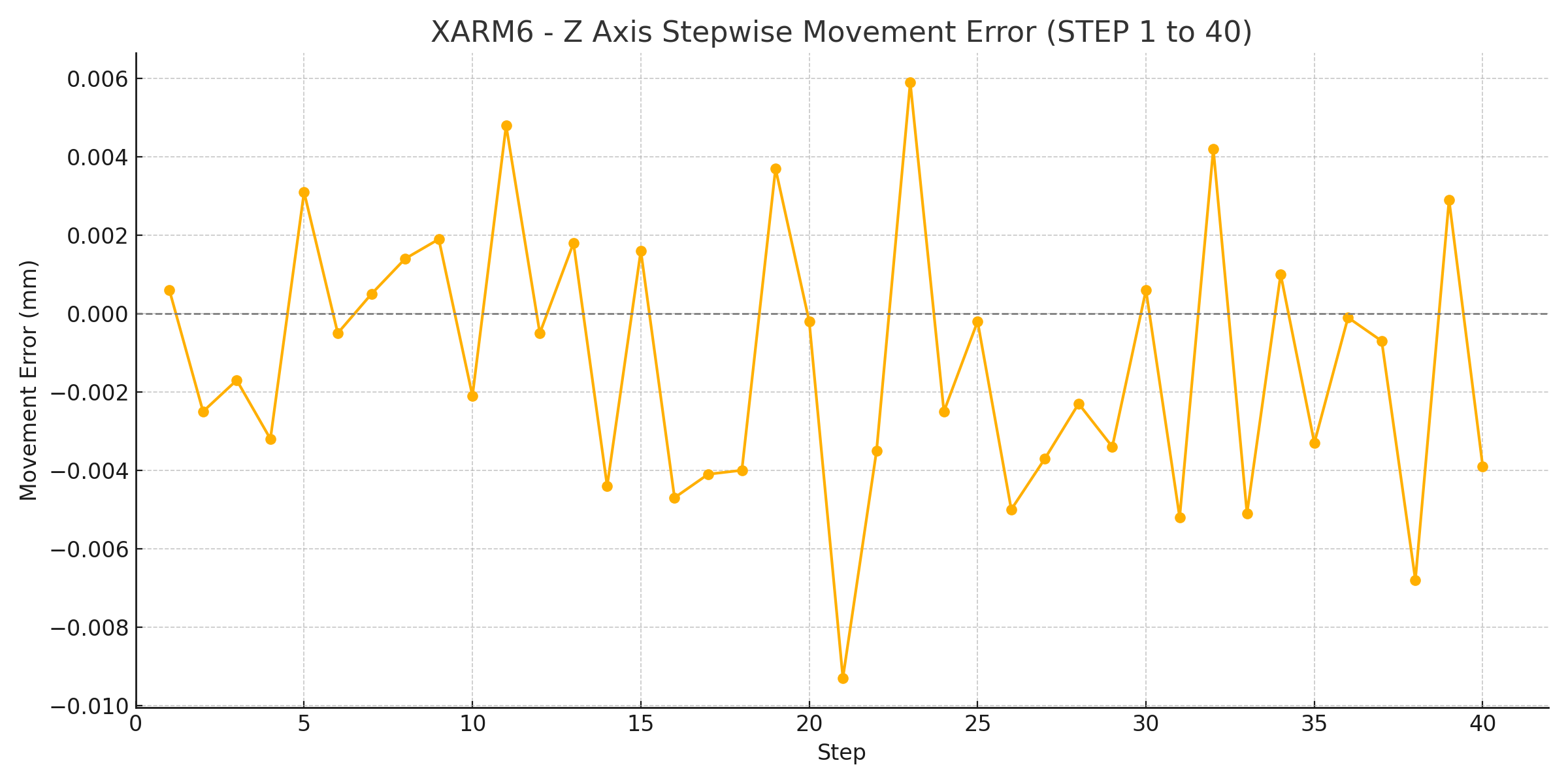

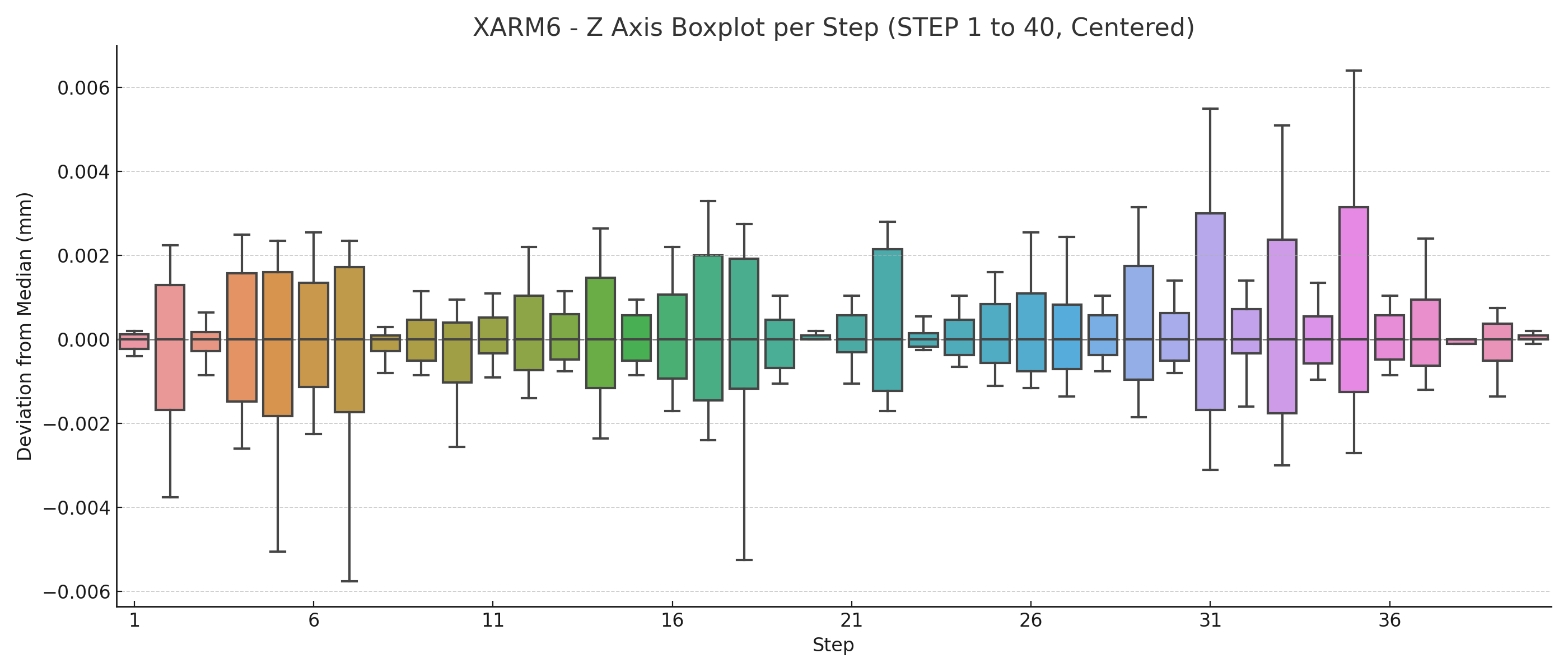

- Each robotic arm starts from the specified initial position and moves in the X+, Y+, and Z+ directions with 0.1 mm step commands, repeated 40 times. A 3-second wait is applied after each movement.

- The actual movement distance is continuously measured by a Keyence GT2 contact-type digital sensor at a sampling frequency of 20 HZ.

Test Conditions

The test is conducted at room temperature with a payload of 0 kg on the robotic arm.

Robot Models and Initial Positions

| Product | Model | Direction | Initial Position |

|---|---|---|---|

| xArm 6 | XI1305 | X+ | [298, 0, 200, 180, 0, 0] |

| xArm 6 | XI1305 | Y+ | [300, -2, 200, 180, 0, 0] |

| xArm 6 | XI1305 | Z+ | [300, 0, 198, 180, 0, 0] |

| 850 | FX8510 | X+ | [298, 0, 200, 180, 0, 0] |

| 850 | FX8510 | Y+ | [300, -2, 200, 180, 0, 0] |

| 850 | FX8510 | Z+ | [300, 0, 198, 180, 0, 0] |

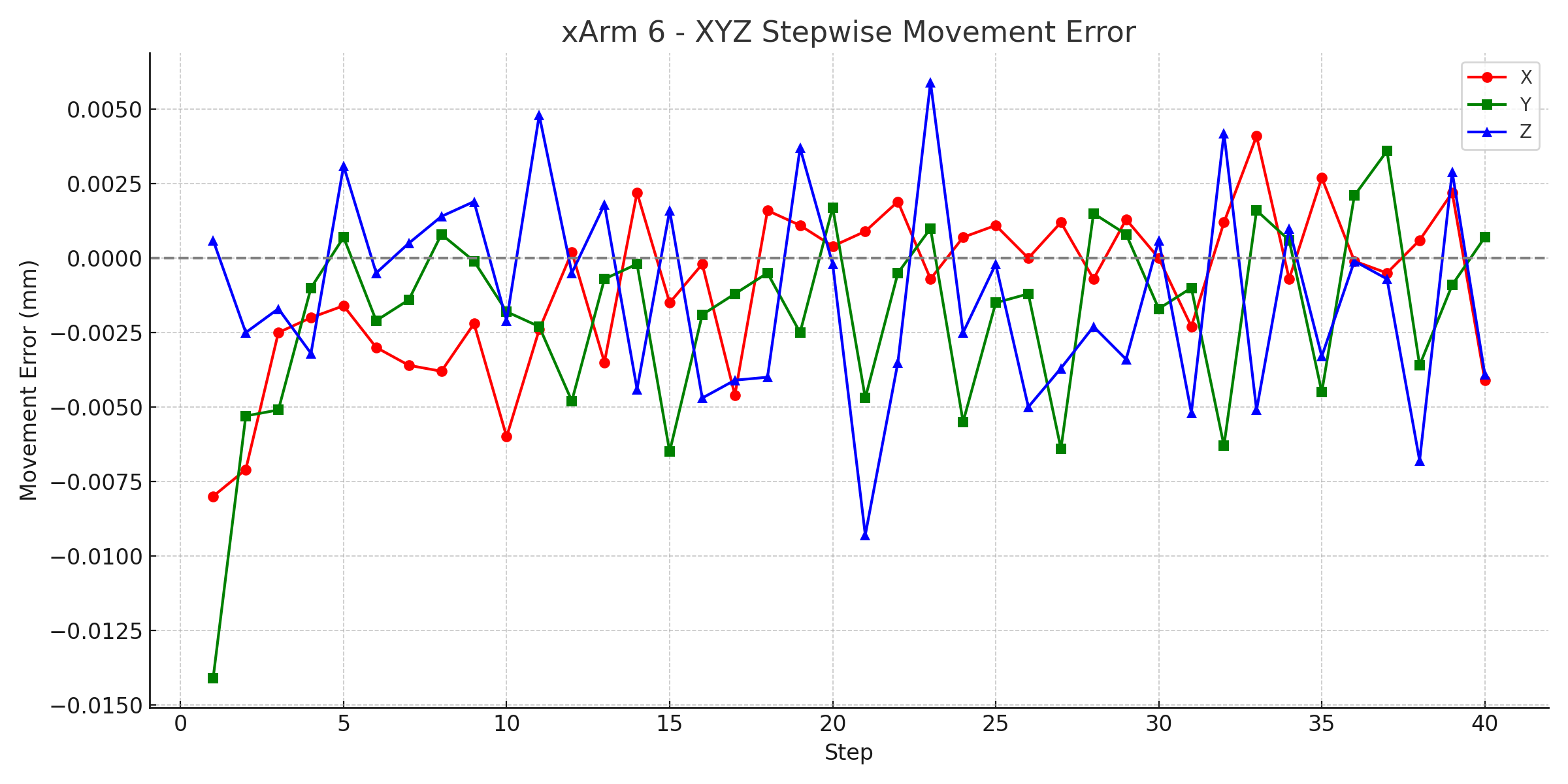

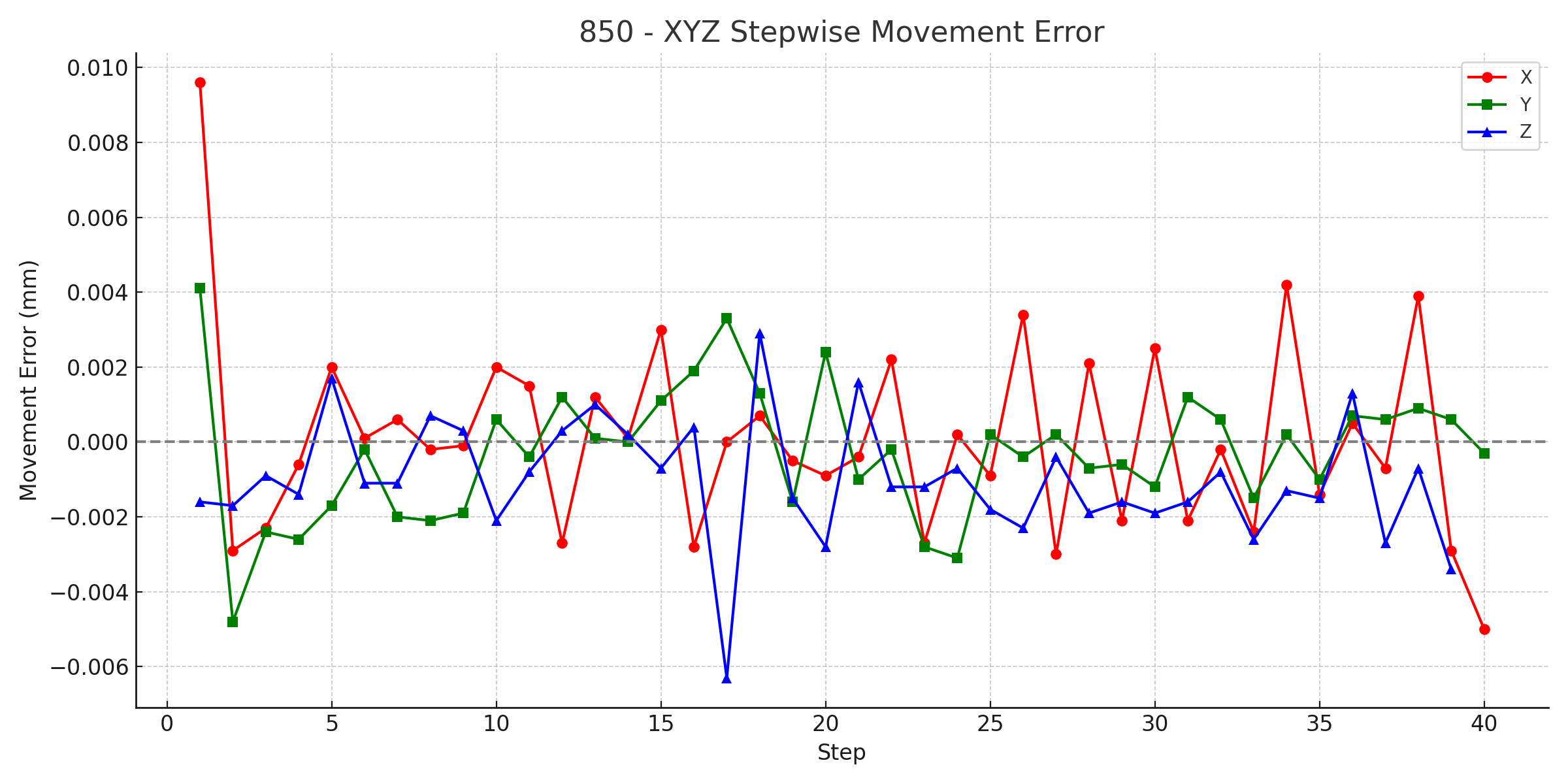

XYZ Movement Error

xArm6 XYZ Error

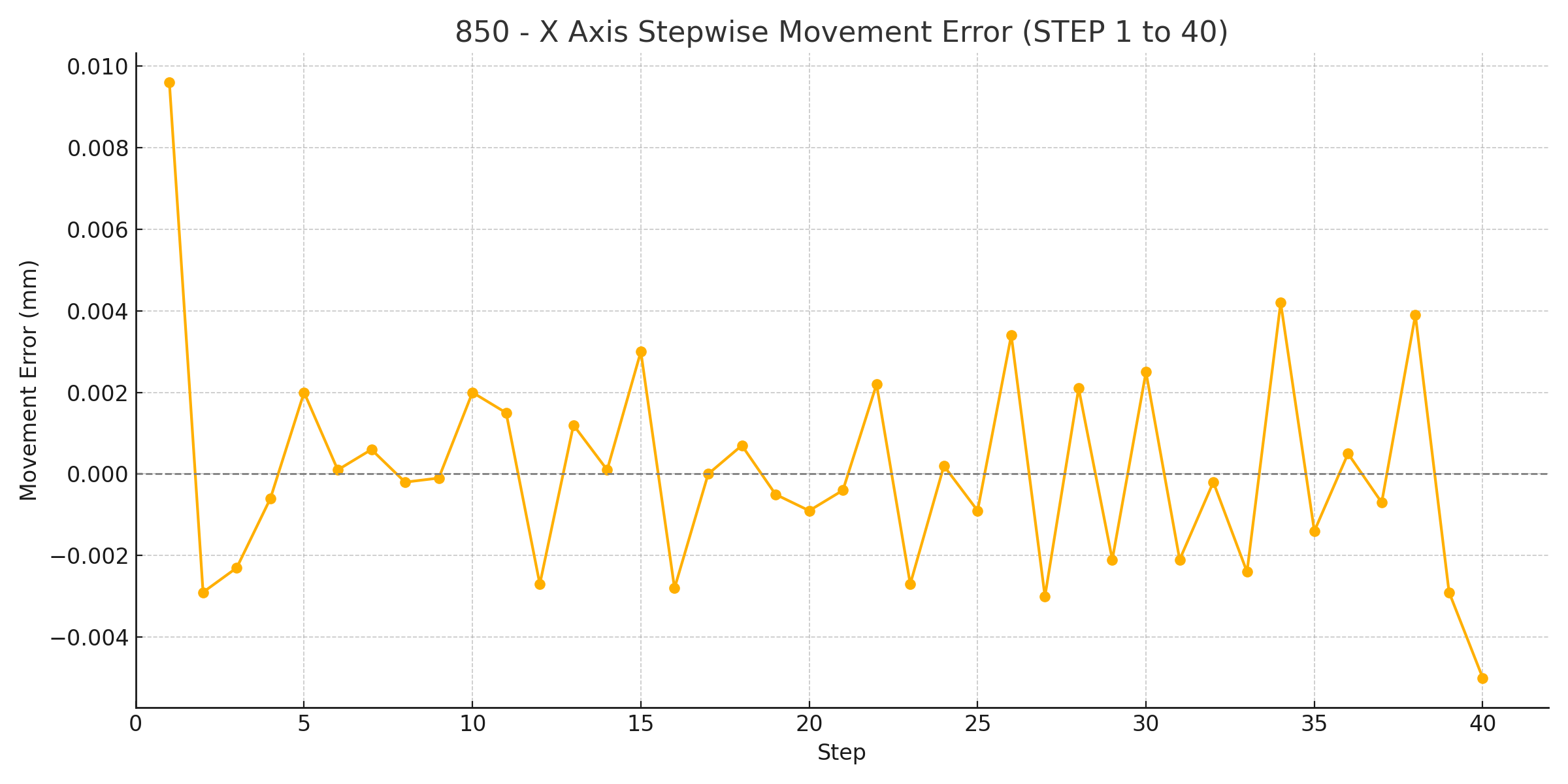

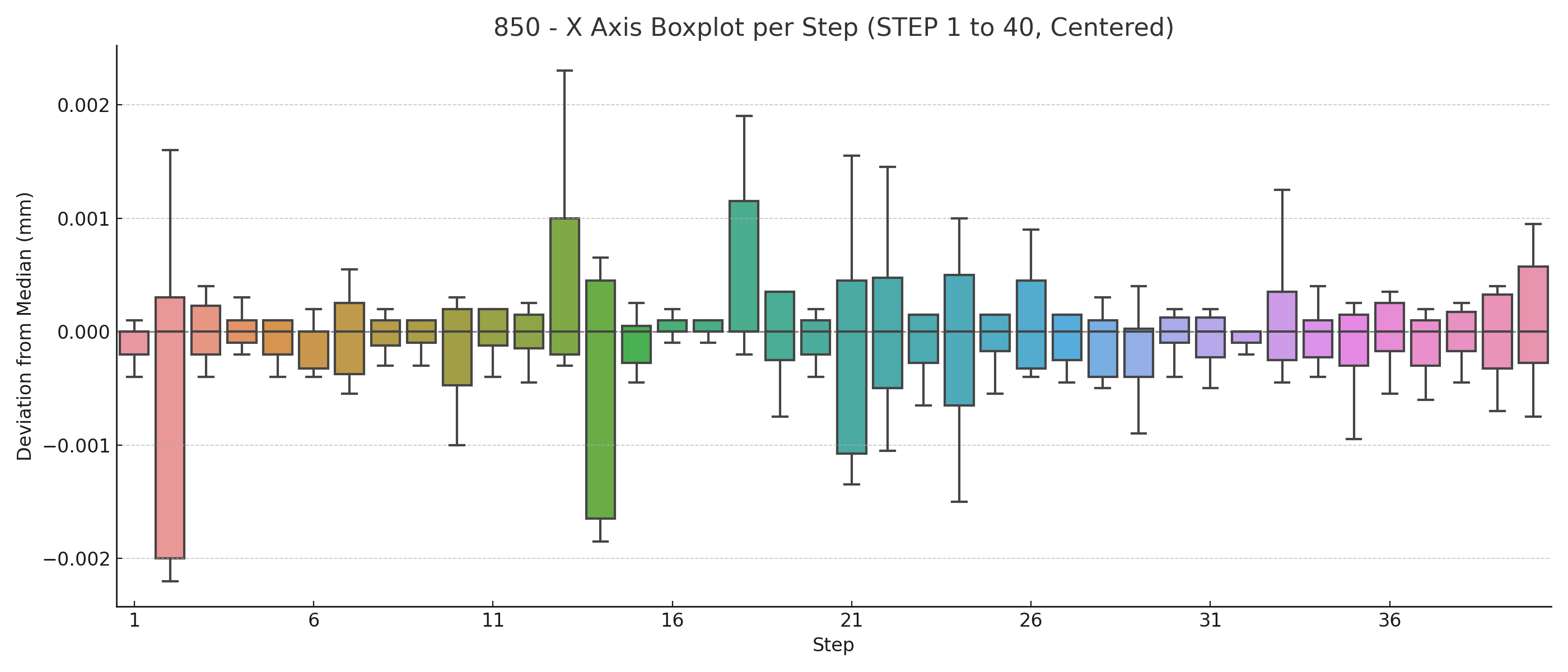

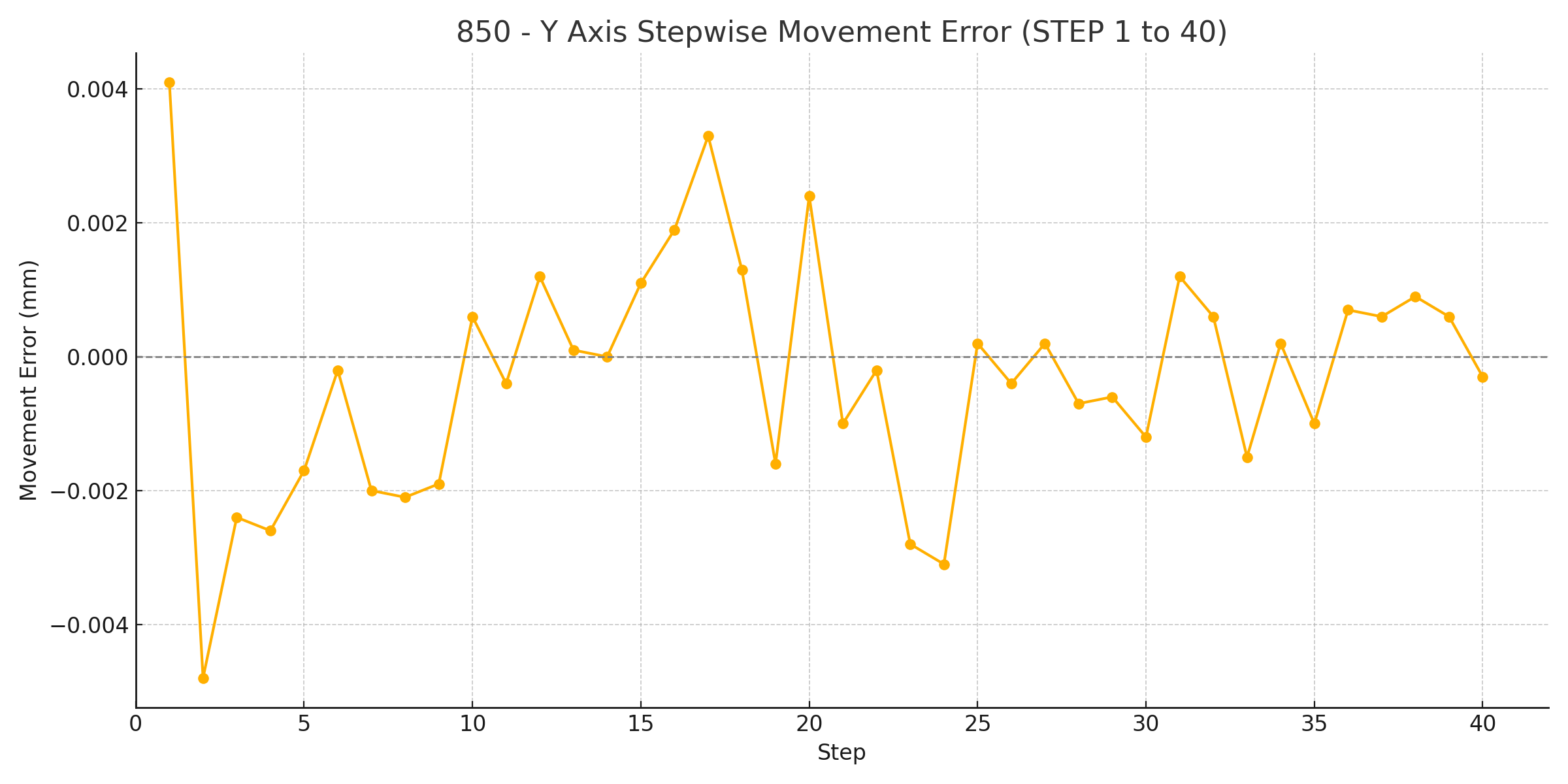

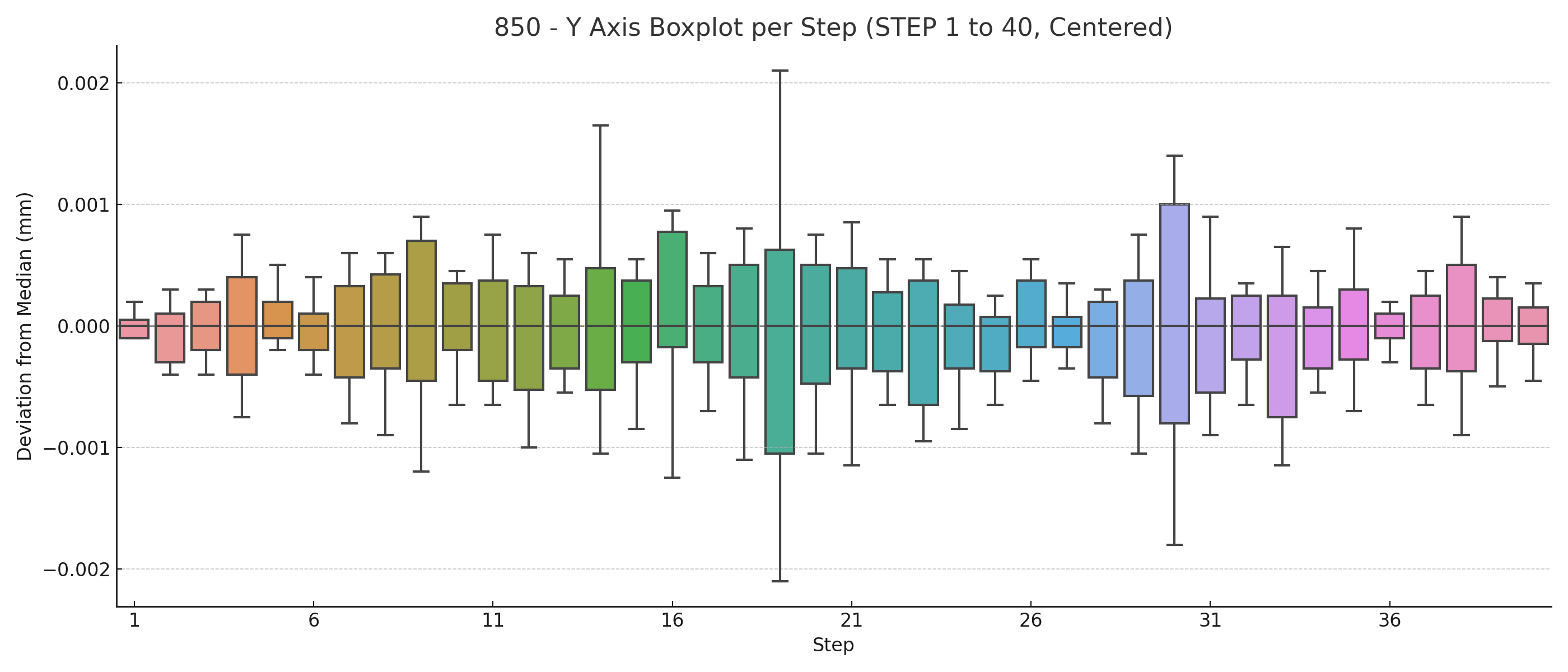

850 XYZ Error

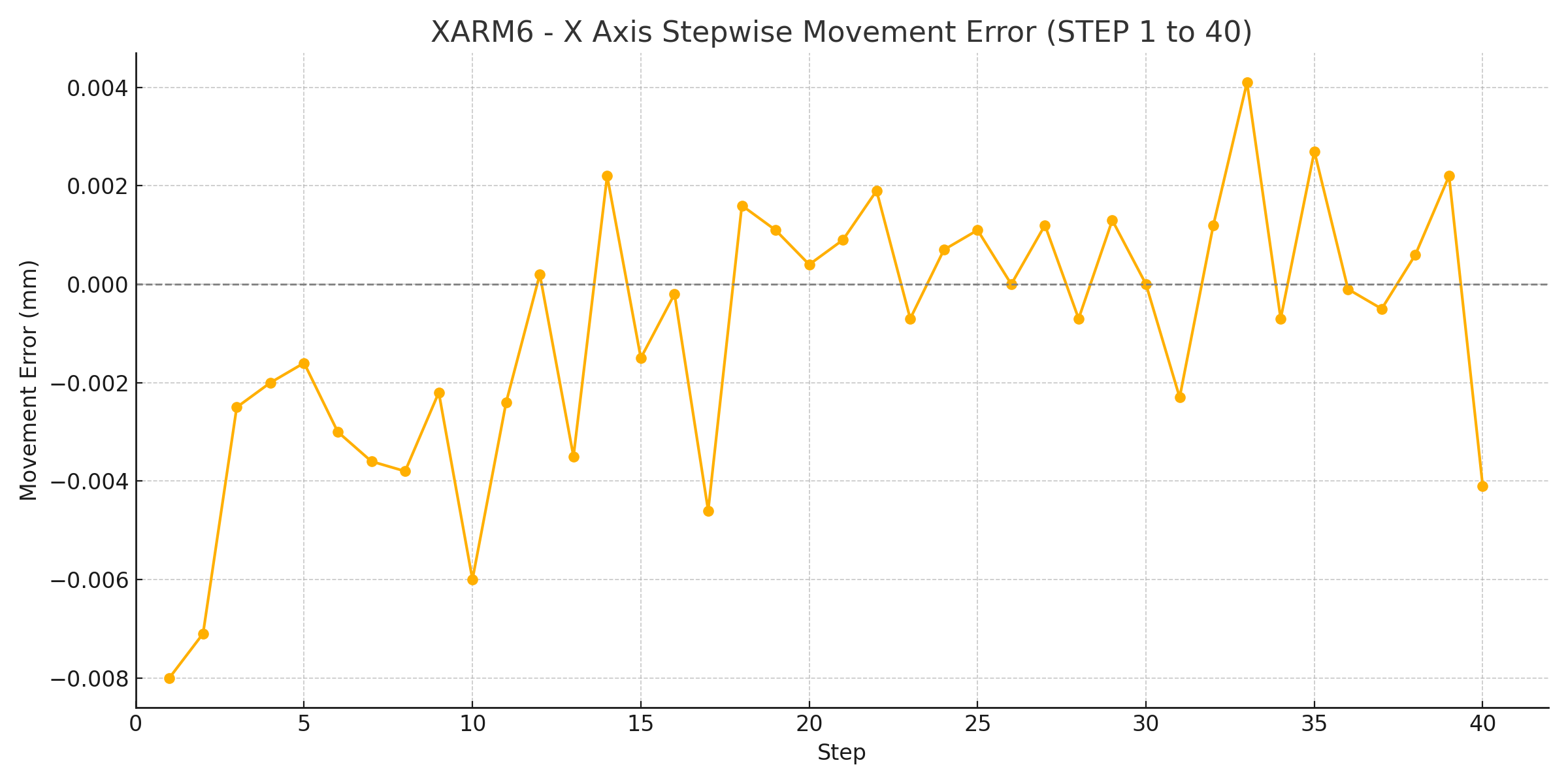

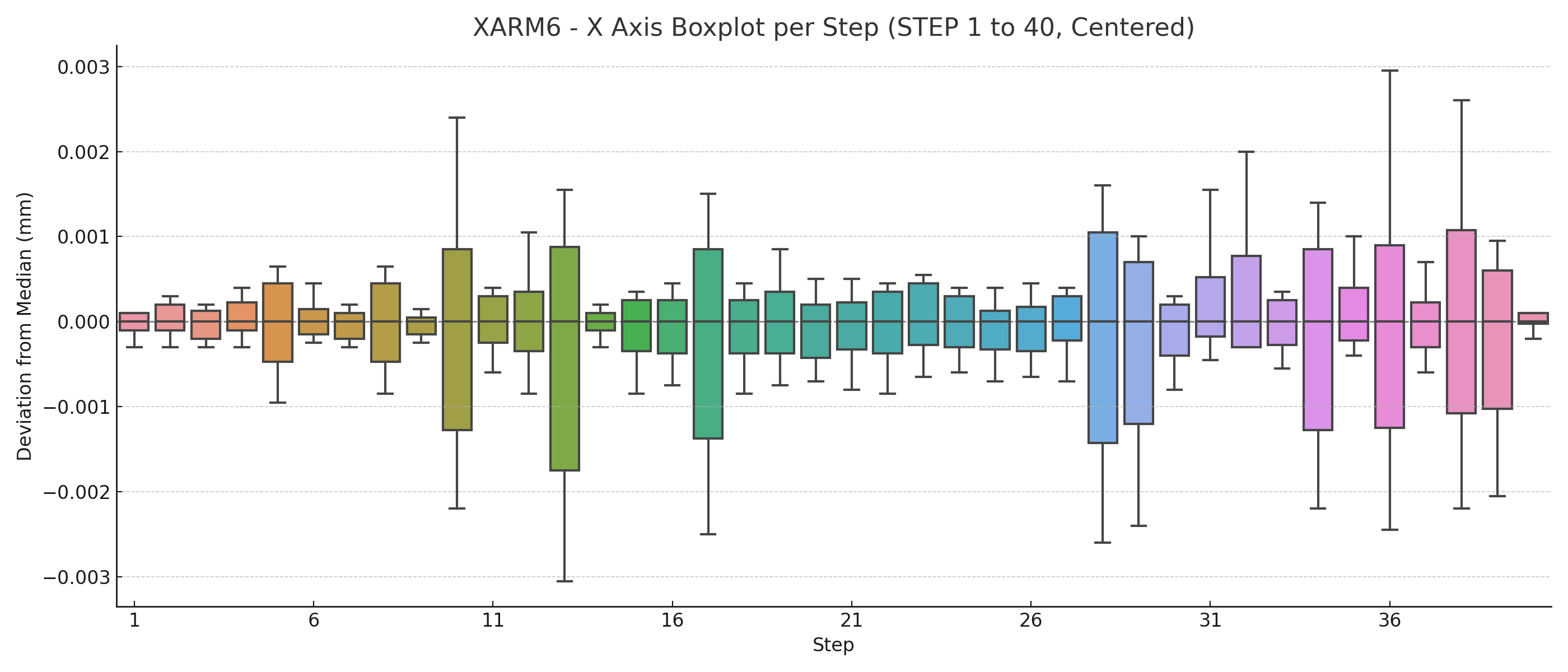

XARM6

X Axis

Y Axis

Z Axis

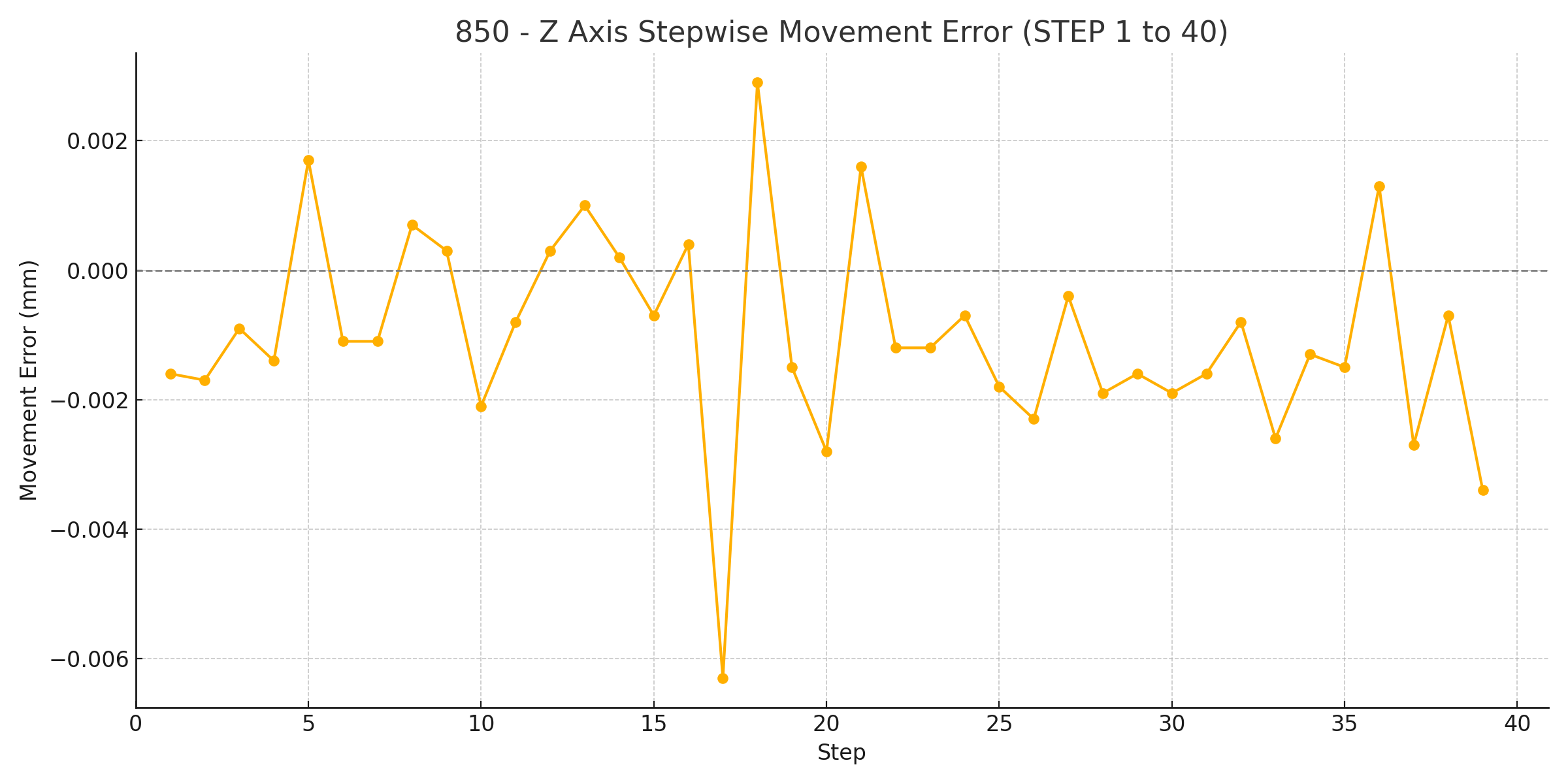

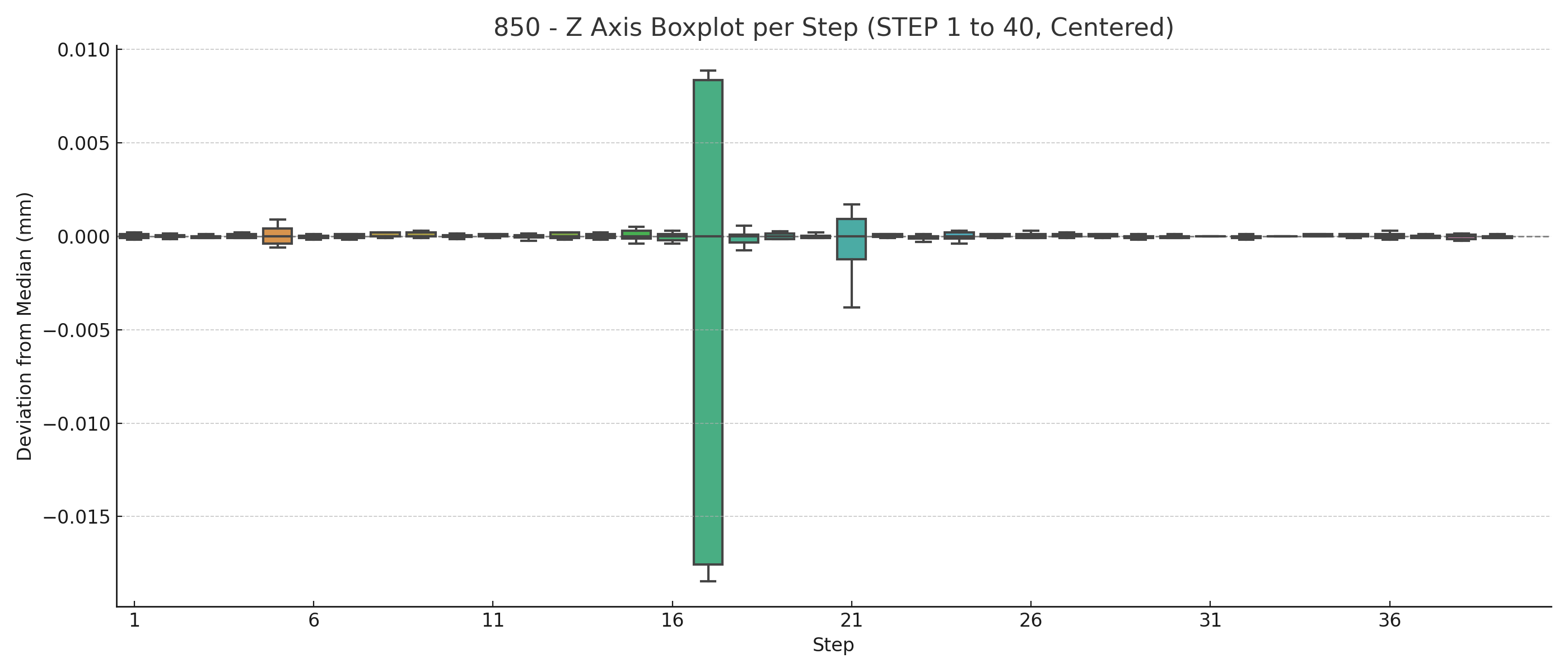

850

X Axis

Y Axis

Z Axis

Raw Data

Raw Data Download: Click Here